| Company Name: Yingkou Chuangxing Technology Co., Ltd. | |

| Company Address: Second Village, Chengdong Office, Old Border District, Yingkou City, Liaoning Province | |

| Contact number:0417-3920188 0417-3920288 | |

| Contact Fax:0417-3920495 |

Website:www.ykcxkj.com

Website : en.ykcxkj.com

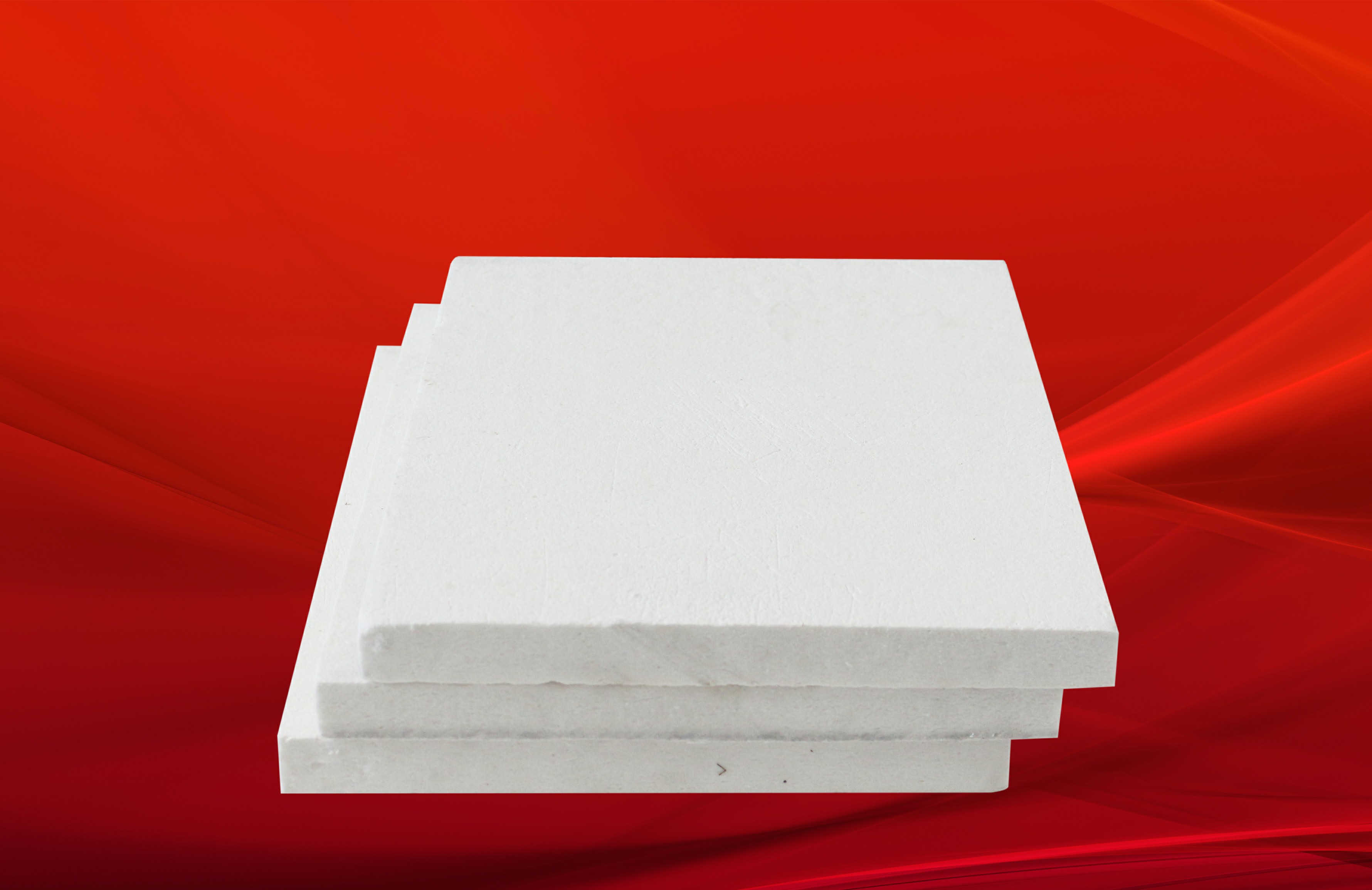

Liaoning magnesia-chrome brick refractory ceramic fiberboard nano-ceramic fiberboard

Aluminum silicate ceramic fiber products have been used and tempered in high temperature kilns and equipment for many years. They have become indispensable materials for heat preservation and sealing in the fields of high temperature kilns and equipment. Their properties are far superior to those of other traditional heat preservation and insulation materials. They have the following characteristics.

1. Refractory Ceramic Fiberboard with Small Volume Weight

Its bulk density is generally between 100 and 330 kg/m3, which is only equivalent to 1/5 to 1/3 of lightweight refractory bricks.

2. Good thermal stability

Because aluminium silicate fibers are elastic and long fibers, they will not produce structural stress even if the temperature changes sharply. Moreover, their products are porous materials interwoven with fibers, and the expansion of monomer fibers can be absorbed by the products themselves. Therefore, with appropriate construction technology, sufficient strength and heat resistance can be obtained.

3. Good chemical stability

Except strong alkali, hydrofluoric acid and phosphoric acid, they are hardly corroded by other chemicals. Aluminum silicate fibers have excellent chemical stability in oxidation and neutral atmosphere. The chemical stability of reducing atmosphere, alkali metal oxides and sulfides is relatively poor, and crystallization easily occurs, which degrades the properties of fibers. The chemical stability of aluminium silicate fibers mainly depends on its chemical composition and impurity content. The chemical stability of pure Al2O3 fibers is the best, while the chemical stability of SiO 2 fibers is not affected by the fluctuation of SiO 2 in the range of 50%-60%.

4. Good heat resistance

According to the variety of raw materials, aluminium silicate fibers can be divided into three types according to the maximum service temperature: low temperature type (below 1000 C), standard type (below 1200 C) and high temperature type (1200 ~ 1400 C), which are much higher than the maximum service temperature (500 ~ 700 C) of fibrous insulation materials such as rock wool and glass wool.

5. Low thermal conductivity

The thermal conductivity of aluminium silicate fibers in high temperature zone is very small, and it has excellent thermal insulation effect. Its thermal conductivity is only 15% of refractory clay brick and 38% of light clay brick at 1000 C. However, its thermal conductivity is closely related to temperature, bulk density, slag ball content and fiber diameter. The thermal conductivity of aluminium silicate fibers decreases with the increase of bulk density, but the decreasing extent decreases gradually. Even when the bulk density exceeds a certain range, the thermal conductivity does not decrease and has an increasing trend.

| Company Name: Yingkou Chuangxing Technology Co., Ltd. |

| Company Address: Second Village, Chengdong Office, Old Border District, Yingkou City, Liaoning Province |

| Contact number:0417-3920188 0417-3920288 |

| Contact Fax:0417-3920495 |

Website:www.ykcxkj.com

Website : en.ykcxkj.com

Sweep and learn more